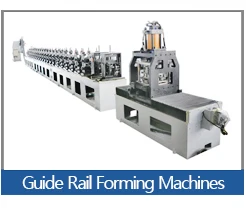

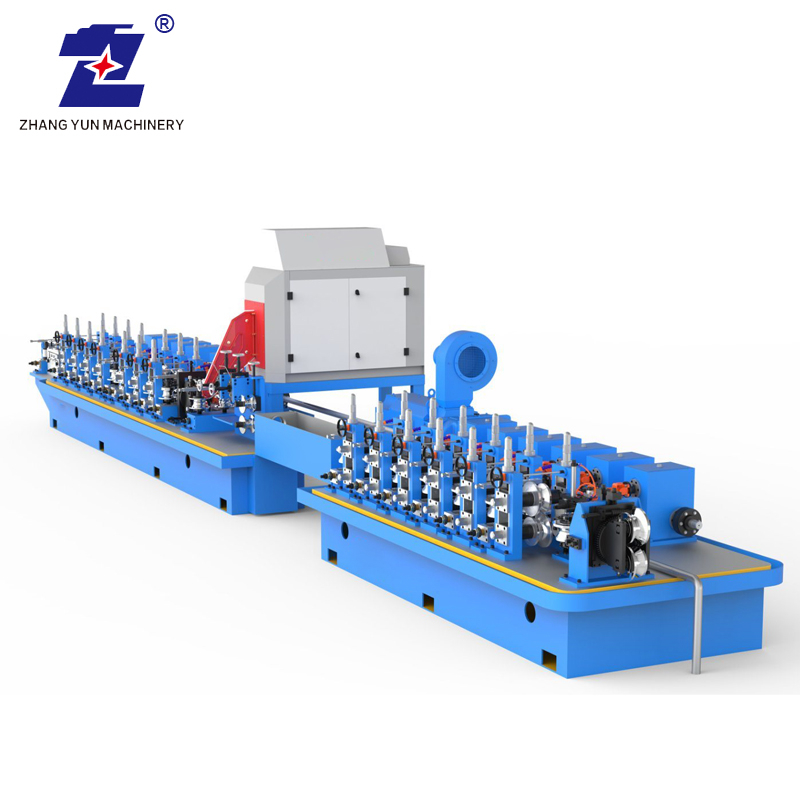

Factory Price Guide Rail Production Line Elevator Guide Rail Making Machine

Here are some guidelines for setting up a guide rail processing production line.

1. Planning and design

Before beginning construction, careful planning and designing are necessary to ensure that the production line meets all requirements. It is essential to consider the number of guide rails needed per day, the available space for the production line, and the type of guide rails required for specific applications. Understanding the production requirements and the type of equipment necessary for the production line is crucial in ensuring the equipment's efficient operation.

2. Equipment selection

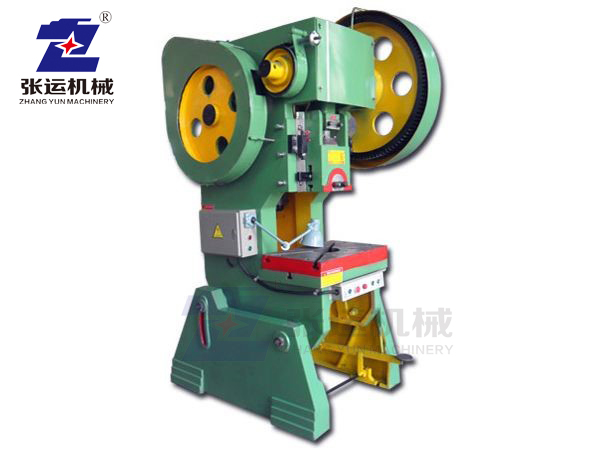

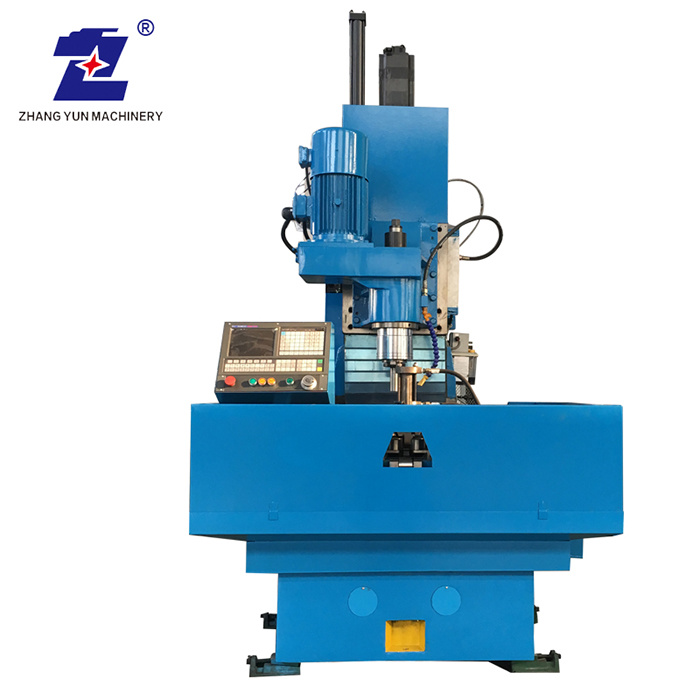

Selecting the right equipment for a guide rail processing line is critical to ensure its efficiency and productivity. Some typical equipment that may be used in the production line may include a cutting machine, a coating machine, and an engraving machine. The equipment chosen should be of high quality, have low maintenance and repair needs, and be able to produce the required number of guide rails per day.

3. Training and workforce

The production line's efficient operation depends heavily on the skills and knowledge of the workforce running it. Appropriate training should be provided to operate the machines safely and correctly. It is essential to ensure all operators understand how to operate and maintain machines and how to detect and solve technical problems that may occur.

4. Choosing the right materials

Choosing the right materials for the guide rails is critical to ensure they are durable and can withstand the expected load, weight, and movement of the product. The quality of the materials selected will determine the quality of the guide rails produced. The raw materials may include aluminum or steel, and they should be inspected, and quality checked before use.

5. Quality control

Quality control is fundamental to meet customer requirements and ensure all guide rails produced are suitable for their intended use. Quality control procedures should be implemented, including checking the raw materials' quality, ensuring the machines are operating correctly, and monitoring the finished product. Quality checks may include dimensional accuracy, surface finish, and hardness.

6. Safety

The equipment on the guide rail processing production line is heavy machinery, and safety should be a top priority. All operators should be fully trained to ensure they understand safety procedures, such as wearing protective clothing, keeping the machine running area clear, and disconnecting machines when repairs or maintenance are necessary.

7. Maintenance and repairs

Maintenance and repair of the guide rail processing production line equipment should be a regular and routine practice. Machines should be examined regularly to determine if any repair or maintenance is necessary. If possible, preventive maintenance should be carried out to reduce downtime and ensure the efficient operation of the production line.

8. Optimizing productivity

Optimizing productivity involves ensuring that the production line is running at the desired speed and quality while producing the required number of guide rails. This could be achieved by incorporating automation technology, such as conveyor systems and robotics, and monitoring the production line's performance to identify areas that need improvement.

Production Capacity

230400pcs/year (300days/year; 2shifts/day, 8hours/shift) based on T89B/5m

| No. | Description | Model | Qty |

| 1 | Automatic Twisting Machine | ZY-ZDJNJ-II | 1 | set |

| 2 | Automatic Straightening Machine | ZY-ZDJZJ-I | 2 | sets |

| 3 | Rust Removing Machine | ZY-CXJ-II | 1 | set |

| 4 | Painting Machine | ZY-YQJ-II | 1 | set |

| 5 | Drying Room | ZY-HF-II | 1 | set |

| 6 | Planer | ZY-B2016 | 3 | sets |

| 7 | Chip Remover | ZY-PXJ1000 | 1 | set |

| 8 | Automatic Detection Machine | ZY-ZDJCJ-I | 1 | set |

| 9 | Automatic Straightening Machine | ZY-ZDJZJ-I | 2 | sets |

| 10 | Milling Machines | ZY-JGSCX-II | 2 | sets |

| Female Milling Machine | ZY-JGSCX-II | 1 | set |

| Male Milling Machine | ZY-JGSCX-II | 1 | set |

| Drilling Machine | ZY-JGSCX-II | 2 | sets |

| Double-head Countersink Drilling Machine | ZY-JGSCX-II | 1 | set |

| One Conveyor Line | ZY-JGSCX-II | 1 | set |

| 11 | Oiling And Filming Machine | ZY-TYTMJ-II | 1 | set |

| 12 | Transverse Conveyor (A) | ZY-HYJ-II | 9 | sets |

| 13 | Jack traverse Converyor (B) | ZY-DSJ-II | 17 | sets |

| 14 | Longitudinal Conveyor (C) | ZY-ZXJ-II | 8 | sets |

| 15 | Independent Roller | ZY-DLJ-I | 1 | set |

| 16 | Control System |

| 1 | set |

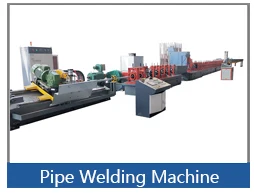

Zhangjiagang City Zhangyun Machinery Manufacturing Co., Ltd. is established in 2002, manufacturer of elevator guide rail processing production line machinery, cold roll forming line machinery and high frequency tube welding line machinery.

Quality Oriented,Technology Innovation is our core concept. Each component of our machines is examined and qualified before assembling; each set of our equipment is fully test run before delivery.

FAQ

1.Q: Are you manufacturer or trading company?

A: We are manufacturer. And we have our own import & export rights.

2.Q: What info you need before you make proposal?

A:Your target type of elevator guide rails; your required production capacity per year; working hours per day, working days per year.

3.Q: What is the MOQ?

A: One set.

4.Q: Do you provide installing and debugging overseas?

A: We send engineers overseas for installation and debugging under client’s request. On line guiding and technical support is for life time.

5.Q: Can you make the machines according to my design or prototype?

A: Yes. We have an experienced engineering team for working out the most suitable design and production plan for the machines you are going to book with us.We can also make the machines according to your design or prototype.

6.Q: How does your factory do regarding quality control?

A: We have Quality Management System Certificate GB/T9001-2016/ISO9001:2015. Each component of our machines is examined and qualified before assembling; each set of our equipment is fully test run before delivery.

7.Q: How can I trust you that machines have passed test running before shipping?

A: 1) We record the test running video for your reference.

2) You are welcomed to observe the test running in our factory.

8.Q: What about your after-sale service?

A: 1) We have an after-sale service team for each customer, including GM, sales Rep, chief engineer, and main engineers for design and making your machines.

2)Overseas after-sale service is available.

3)We provide life time online technical support.

9. Q: What should I do if I just start a new business?

A: Contact us immediately,we provide free consultant pre-sales service.

We are domestic leading factory in elevator guide rail processing equipment field. We are familiar with our machines and we have many successful user cases. We know the development history and the latest trends. We can make the most reasonable proposal for you.

10. Q:Can I visit you factory to check machines on-site?

A: We are manufacturer, we have our own R&D department and workshops for more than 20 years. We warmly welcome your visit and checking machines in our factory.